Our prior blog posts have already recognised that the correct assembly technique is an important aspect in relation to the performance of your application. After a detailed look at the pros and cons of mechanical assembly, insert moulding and over moulding, gluing is next up for discussion.

Gluing

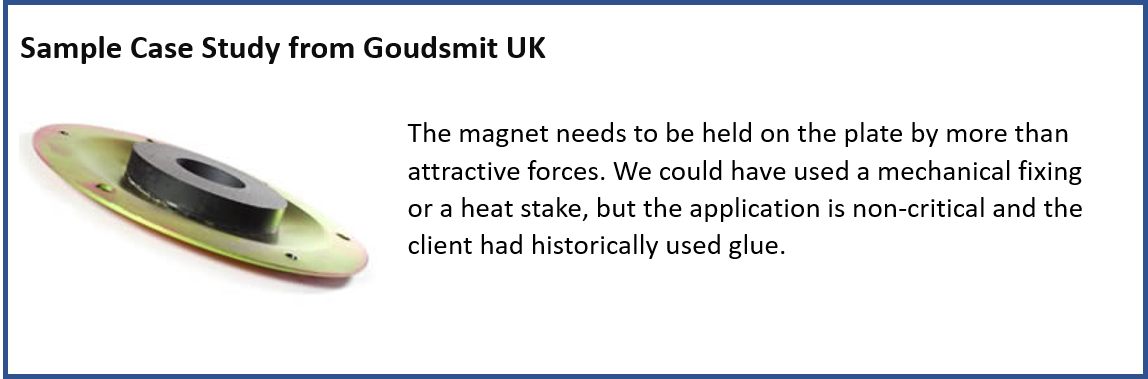

Many manufactures today use adhesives for product assembly, and Goudsmit UK are no different. We know exactly how much to use and the best curing processes, both of which are essential to ensure the product functions correctly. Additionally, to further ensure the correct functioning of the product over time, Goudsmit UK carry out considerable testing cycles; including environmental and fatigue testing – guaranteeing you quality products every time.

Characteristics of gluing

- Suitable for practically all materials.

- Heating is rarely necessary, making production quicker.

- The correct choice of adhesive is vital to ensure the functionality of the product.

In contrast to welding and soldering, gluing is a joining technique that is suitable for connecting almost any materials together. Moreover, the materials to be joined do not have to be heated during gluing. This applies to all but a few applications, in which the curing takes place in an autoclave; for example, this can be seen in the aerospace industry.

How to achieve the perfect gluing assembly

To achieve a good adhesive connection there are two key elements:

- The choice of glue.

- A carefully controlled gluing process.

Getting these elements correct is vital for the success of the assembly. For this reason, we place a huge emphasis on both elements to ensure we provide our customers with a high-quality product assembly.

The gluing process

Simply, the gluing process involves four steps which carried out accordingly will guarantee a high-quality gluing product assembly:

- All surfaces must be cleaned.

- Ensure that the substrates are suitable.

- Apply the adhesive correctly.

- Check the chemical reaction of the adhesive.

The benefits of gluing

- Gluing eliminates the corrosion associated with dissimilar metals joining with different galvanic potential.

- Gluing does not produce any deformation in the materials, thus reducing the manufacturing cost and improving the aesthetics of the product.

- Avoids any damage to the structure of the product as it does not produce any mechanical aggression to the substrate.

- Enables flexibility in the design of the product as well as an improvement in its aesthetics.

The drawbacks of gluing

Although gluing provides an array of benefits which make it hugely popular in the manufacturing industry, it also presents a few drawbacks:

- Prior to the adhesive application process, surface preparation is required to achieve good adhesion between the adhesive and the substrate.

- The final strength of the adhesive bond is not obtained immediately, unlike the case with a rivet or a screw, the adhesive needs time to cure.

Applications using gluing

Applications include:

- Aerospace

- Automotive

- Solar

- Industrial

- Electronics

- Construction

Precautions when gluing

- Do not use a hot glue gun on neodymium magnets. While this adhesive works exceptionally well on many other surfaces, the high temperatures may possibly demagnetise the magnets.

Gluing

We have years of experience, so there is no other supplier that can provide better results. Contact us today for more information at info@goudsmit.co.uk or on +44 (0) 2890 271 001.

For more information download our products and services brochure.