AlNiCo (Aluminium–Nickel–Cobalt) magnets are trusted where heat resistance, stability, and reliability are critical. With operating ranges up to 500 °C, they outperform neodymium or ferrite in high-temperature environments and offer excellent corrosion resistance.

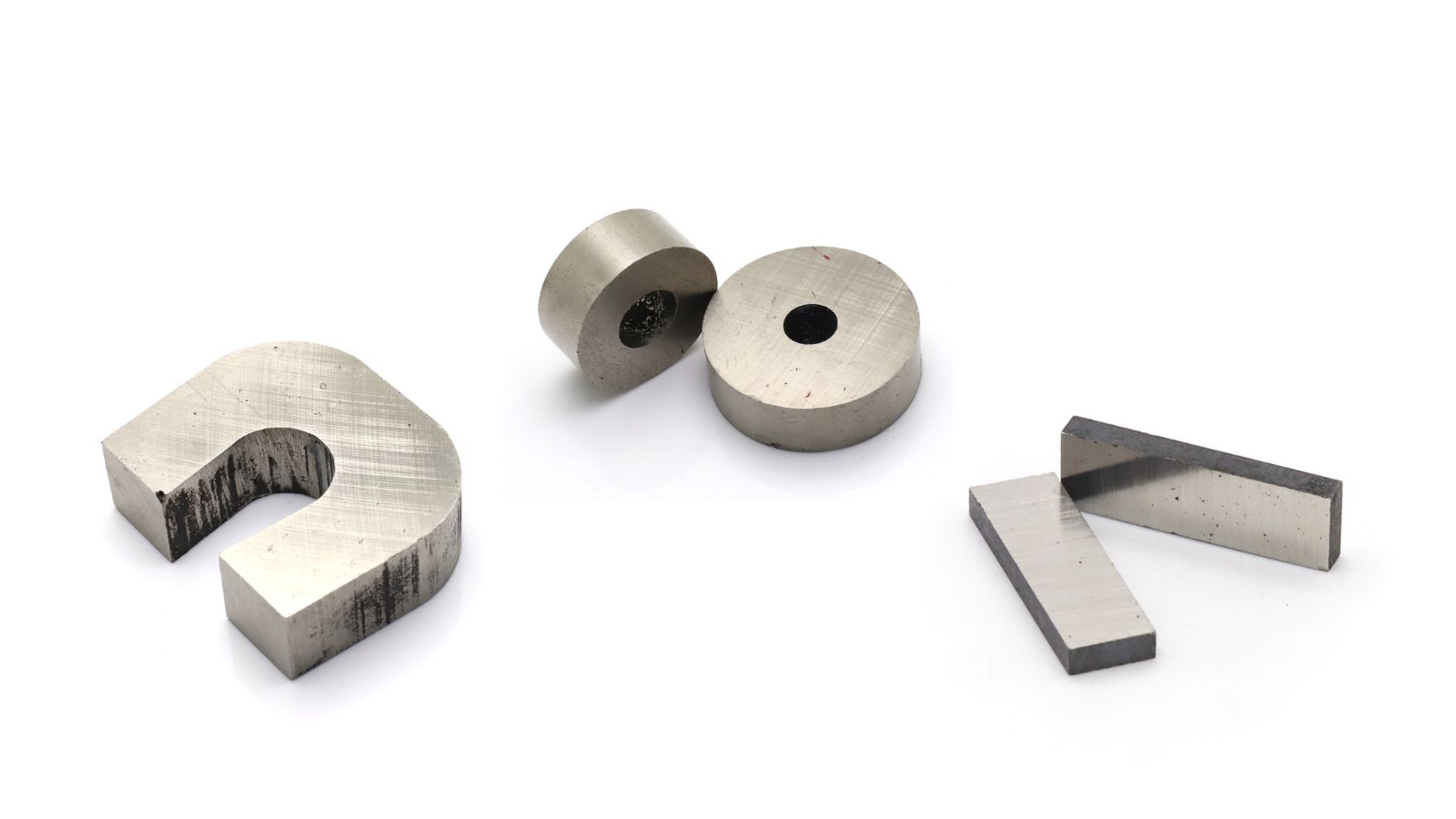

Our AlNiCo magnets are available in various forms, including blocks, discs, rings, and cylinders. We use only high-quality materials and advanced manufacturing processes to ensure that our magnets have consistent performance and reliability.

Our team of experts can help you select the right AlNiCo magnet for your application and provide technical support to ensure that you get the most out of your magnets.

When you choose GUK Magnetics as your magnet manufacturing partner, you can expect:

High-Quality Supply: Manufactured from premium alloys for consistent performance.

Custom Options: Shapes, grades, and magnetisation tailored to your specification.

Application Expertise: Support in selecting grades for heat resistance and stability.

Engineering Support: Advice on tolerances and integration into assemblies.

Reliable Delivery: Realistic lead times, stockholding options, and UK-based support.

AlNiCo magnets are a type of permanent magnet made from aluminium, nickel, and cobalt, known for their high magnetic strength, excellent temperature stability, and corrosion resistance. Like all magnets, they have advantages and disadvantages that should be considered when selecting them for use in various applications. Here are some of the advantages and disadvantages of AlNiCo magnets: Advantages:

Disadvantages:

Alnico magnets are known for their inherent corrosion resistance. While Alnico is frequently commended for its robust resistance to corrosion, the extent of this resistance is contingent upon both the Alnico grade and the specific chemicals to which it is exposed. Due to its trace free iron content, Alnico might display susceptibility to surface corrosion in watery environments. However, it boasts exceptional resistance when interacting with substances like motor oil, organic solvents, petrol, and alcohol. Furthermore, Alnico displays commendable resistance against dilute organic acids and hydrogen peroxide, but prolonged exposure to salt water, potent alkali solutions, or inorganic acids may induce corrosion over time. For enhanced protection, options are available to layer Alnico with protective substances such as Ni, Zn, or paint. While not always deemed essential, protective or aesthetic coatings are occasionally applied to Alnico magnets. A prevalent choice is a distinctive red hue, leading many to colloquially refer to Alnico magnets as 'Red Magnets'. It's noteworthy that ferrite magnets in pot magnet assemblies, also sometimes don a red exterior and share this name. Other colour variants, including black, can be opted for Alnico upon request.

| Grade | Remanence | Coercivity | Max Energy Product | Temp Coefficient | Max working | MMPA | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Br | HcB | HcJ | (BH)max | TK(Br) %/K | TK(Hcj) %/K | Tw max | ||||||

| kGs | mT | kOe | kAlrn | kOe | kA/m | MGOe | KJ/m³ | °C | ||||

| ISOTROPIC CAST ALNICO | ||||||||||||

| LN10 | 6.5 | 650 | 0.48 | 38 | 0.5 | 40 | 1.25 | 10 | -0.035 | -0.025 | 450 | ALNICO 3 |

| LNG12 | 7.5 | 750 | 0.56 | 45 | 0.58 | 46 | 1.5 | 12 | -0.03 | -0.02 | 450 | ALNICO 2 |

| LNGT18 | 5.5 | 550 | 1.13 | 90 | 1.21 | 97 | 2.25 | 18 | -0.025 | 0.01 | 550 | ALNICO 8 |

| ANISOTROPC CAST ALNICO | ||||||||||||

| LNG34 | 11 | 1100 | 0.63 | 50 | 0.65 | 52 | 4.25 | 34 | -0.02 | 0.01 | 525 | ALNICO 5 |

| LNG37 | 11.8 | 1180 | 0.61 | 49 | 0.64 | 51 | 4.63 | 37 | -0.02 | 0.01 | 525 | |

| LNG40 | 12 | 1200 | 0.63 | 50 | 0.65 | 52 | 5 | 40 | -0.02 | 0.01 | 525 | |

| LNG44 | 12.5 | 1250 | 0.65 | 52 | 0.68 | 54 | 5.5 | 44 | -0.02 | 0.01 | 525 | |

| LNGT34 | 11.5 | 1150 | 0.73 | 58 | 0.75 | 60 | 3.5 | 28 | -0.02 | 0.03 | 525 | ALNICO 6 |

| LNG52 | 13 | 1300 | 0.7 | 56 | 0.73 | 58 | 6.5 | 52 | -0.02 | 0.03 | 525 | ALNICO 5DG |

| LNG60 | 13.5 | 1350 | 0.73 | 58 | 0.75 | 60 | 7.5 | 60 | -0.02 | 0.03 | 525 | ALNICO 5-7 |

| LNGT38 | 8 | 800 | 1.38 | 110 | 1.4 | 112 | 4.75 | 38 | -0.025 | 0.01 | 550 | ALNICO 8 |

| LNGT40 | 8.5 | 850 | 1.44 | 115 | 1.46 | 117 | 5 | 40 | -0.025 | 0.01 | 550 | |

| LNGT44 | 9 | 900 | 1.44 | 115 | 1.46 | 117 | 5.5 | 44 | -0.025 | 0.01 | 550 | |

| LNGT36J | 7.2 | 720 | 1.88 | 150 | 1.9 | 152 | 4.5 | 36 | -0.025 | 0.01 | 550 | ALNICO 8HC |

| LNGT6O | 10 | 1000 | 1.38 | 110 | 1.4 | 112 | 7.5 | 60 | -0.025 | 0.01 | 550 | ALNICO 9 |

| LNGT72 | 10.5 | 1050 | 1.44 | 115 | 1.46 | 117 | 9 | 72 | -0.025 | 0.01 | 550 | |

| LNGT80 | 10.8 | 1080 | 1.5 | 120 | 1.53 | 122 | 10 | 80 | -0.025 | 0.01 | 550 | |

| ISOTROPIC SINTERED ALNICO | ||||||||||||

| FLNG10 | 6.5 | 650 | 0.5 | 4.0 | 0.53 | 42 | 1.25 | 10 | -0.03 | -0.02 | 450 | ALNICO 3 |

| FLNG12 | 7.5 | 750 | 0.56 | 45 | 0.58 | 46 | 1.5 | 12 | -0.03 | -0.02 | 450 | ALNICO 2 |

| FLNGT18 | 6 | 600 | 1.19 | 95 | 1.23 | 98 | 2.25 | 18 | -0.025 | 0.01 | 550 | ALNICO 8 |

| FLNGT20 | 6.2 | 620 | 1.25 | 100 | 1.31 | 105 | 2.5 | 20 | -0.025 | 0.01 | 550 | |

| ANISOTROPIC SINTERED ALNICO | ||||||||||||

| FLNG34 | 11.5 | 1150 | 0.6 | 48 | 0.63 | 50 | 4.25 | 34 | -0.02 | 0.01 | 525 | ALNICO 5 |

| FLNGT28 | 11 | 1100 | 0.73 | 58 | 0.75 | 60 | 3.5 | 28 | -0.02 | 0.03 | 525 | ALNICO 6 |

| FLNGT36J | 7.2 | 720 | 1.88 | 150 | 1.9 | 152 | 4.5 | 36 | -0.025 | 0.01 | 550 | ALNICO 8HC |

| FLNGT38 | 8 | 800 | 1.38 | 110 | 1.4 | 112 | 4.75 | 38 | -0.025 | 0.01 | 550 | ALNICO 8 |

| FLNGT44 | 8.5 | 850 | 1.5 | 120 | 1.53 | 122 | 5.5 | 44 | -0.025 | 0.01 | 550 | |

| FLNGT48 | 9.2 | 920 | 1.56 | 125 | 1.59 | 127 | 6 | 48 | -0.025 | 0.01 | 550 | |

| BONDED ALNICO (BEARING) | ||||||||||||

| B-LNG7 | 3.1 | 310 | 1.00 | 79.63 | 1.30 | 103.5 | 0.85 | 6.77 | -0.02 | 0.01 | 200 | |

| B-LNG8 | 3.4 | 340 | 1.05 | 83.612 | 1.35 | 107.5 | 1.00 | 7.96 | -0.02 | 0.01 | 200 | |

AlNiCo magnets are a proven solution where high temperatures, long-term magnetic stability, and corrosion resistance are required. They are widely used in motors, sensors, aerospace systems, and specialist instrumentation.

When considering AlNiCo, buyers should keep in mind that AlNiCo offers excellent stability but lower magnetic strength than neodymium. AlNiCo is also typically higher cost than ferrite.

At GUK Magnetics, our engineers can:

Recommend the right AlNiCo grade for your operating temperature.

Advise on tolerances and magnetisation direction for your application.

Compare AlNiCo with neodymium, SmCo, or ferrite to ensure best fit.

Provide supply options from small test batches to large OEM orders.

Talk to our team today — share your drawings or application details and we’ll help you determine if AlNiCo is the right choice for your project.

Give us a call

+44 (0) 2890 271 001Send us an email

info@gukmagnetics.co.uk