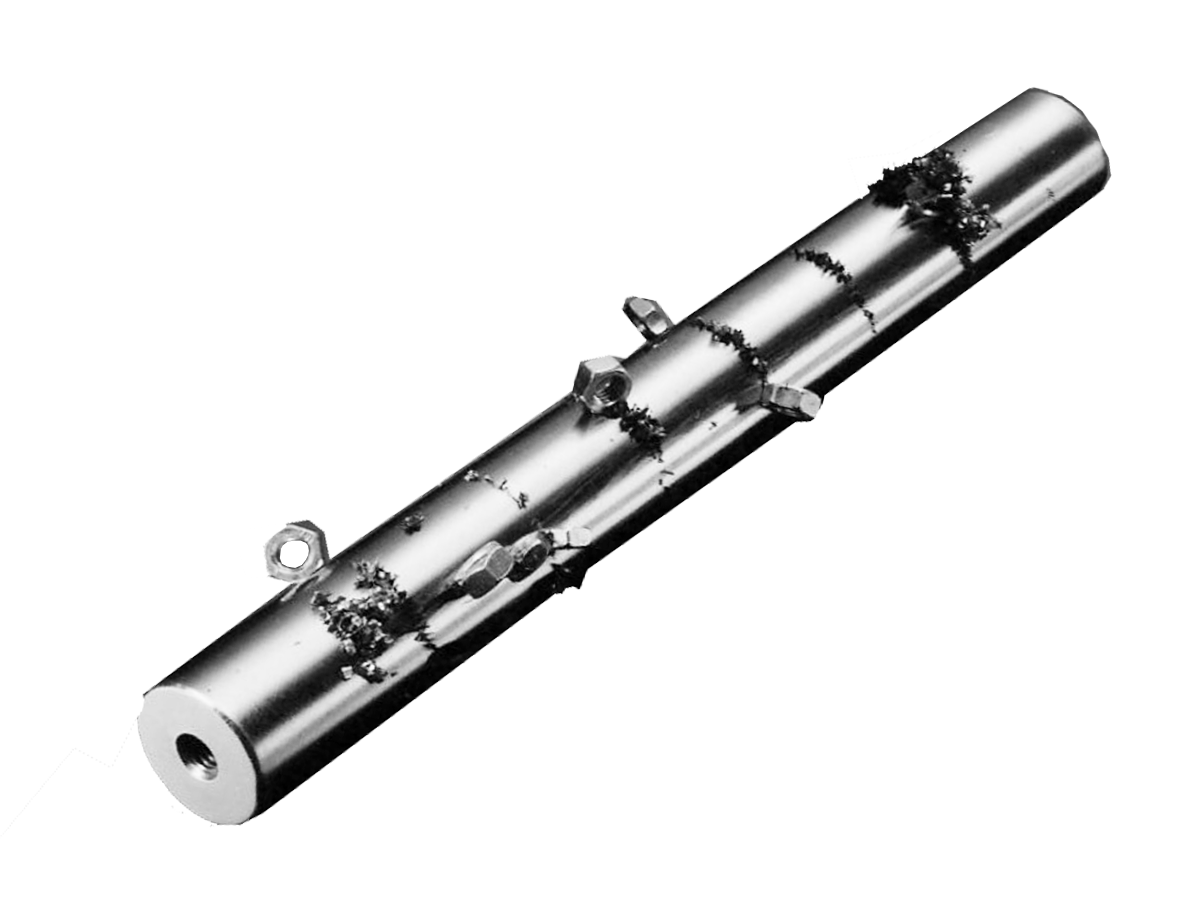

Magnetic Bars

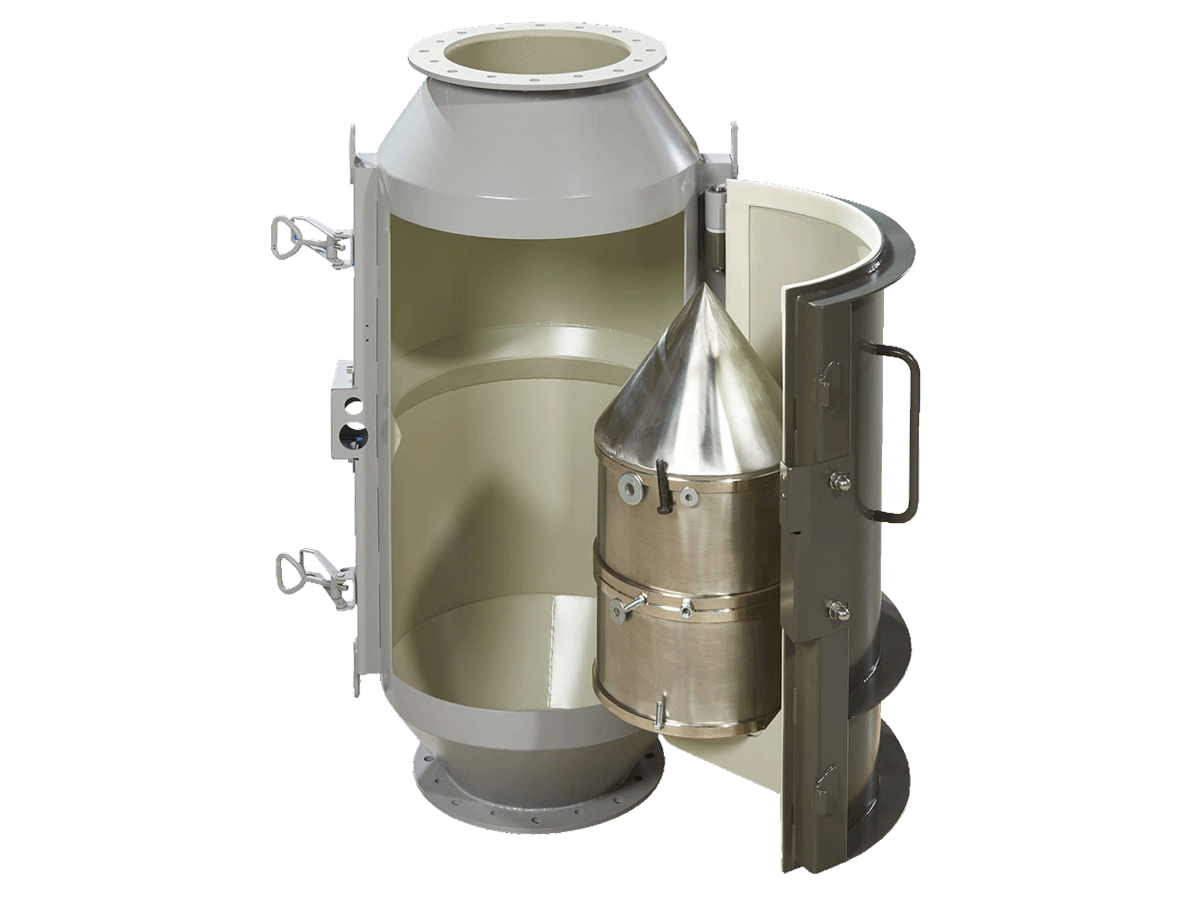

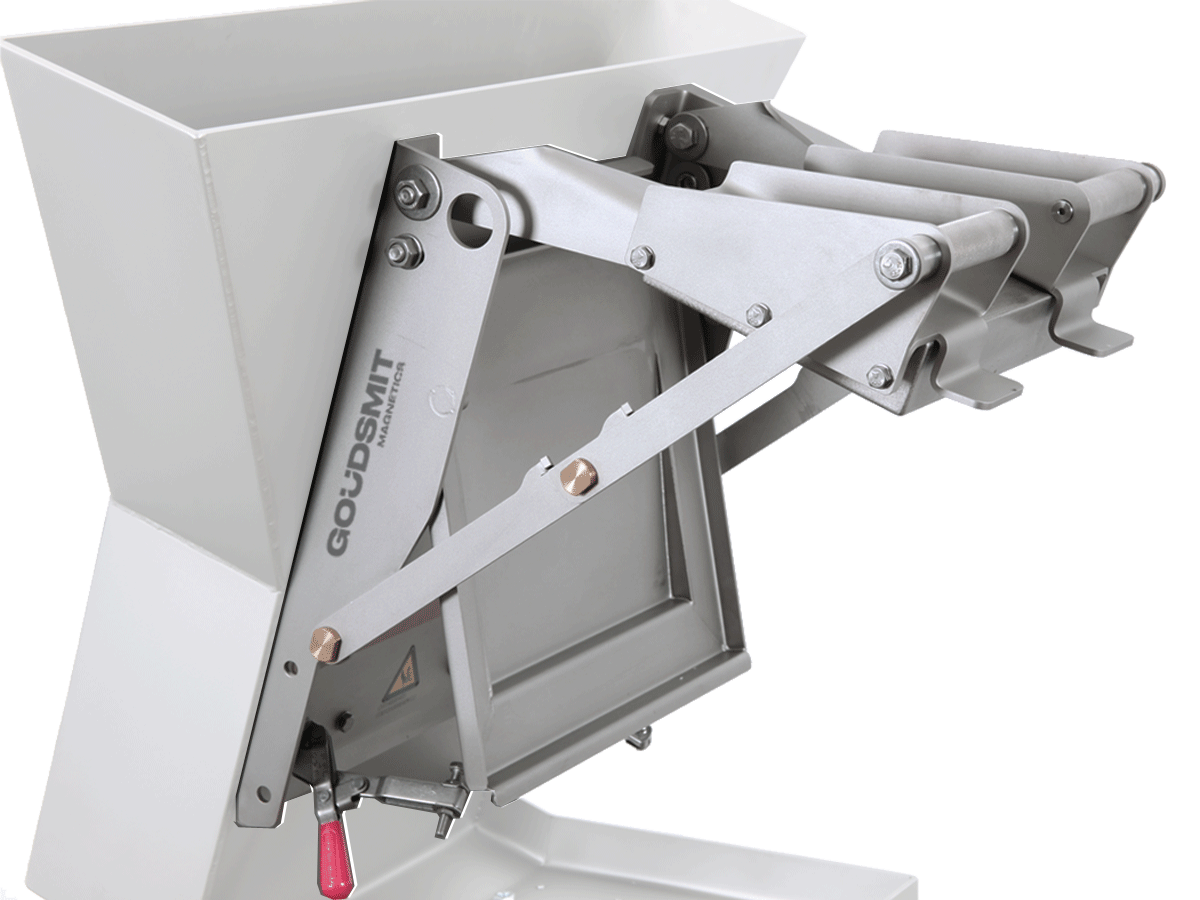

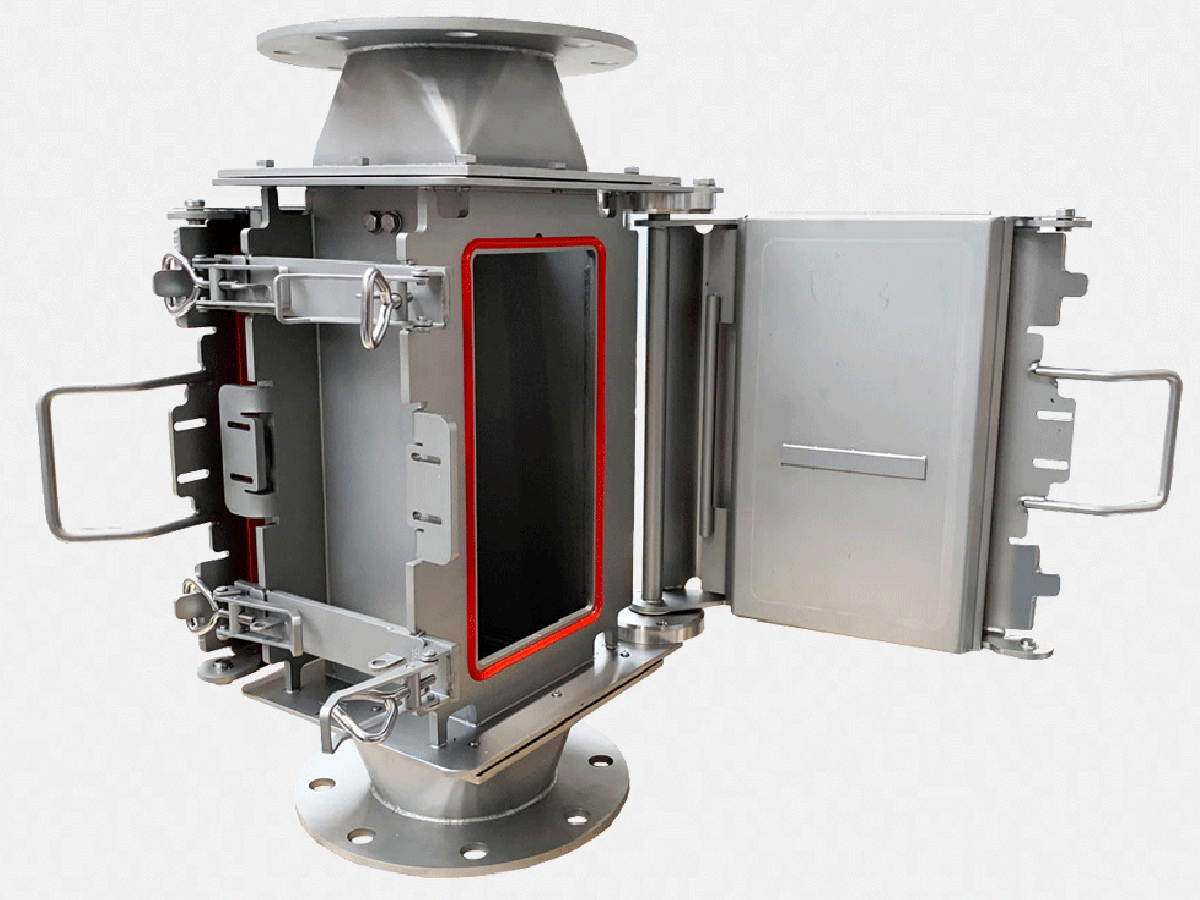

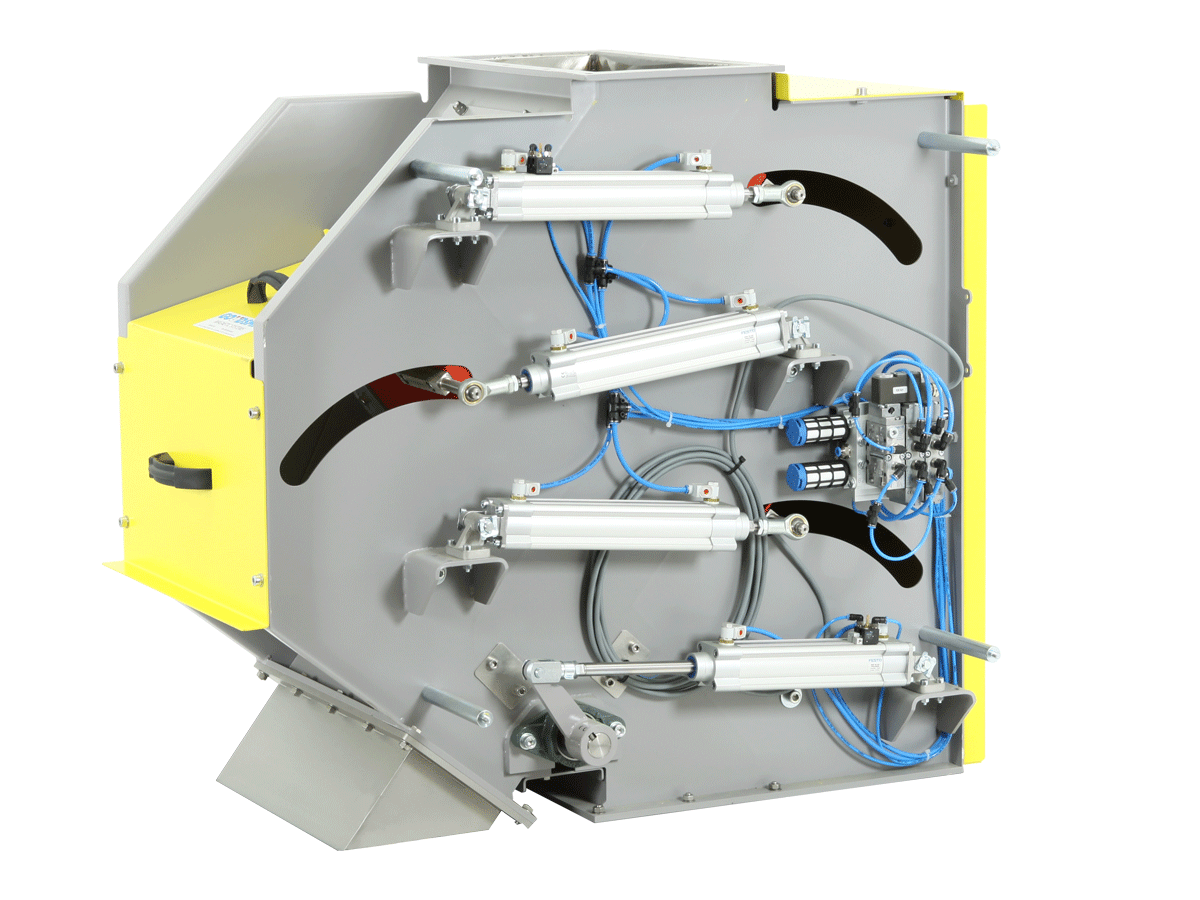

These very strong neodymium magnetic bars are designed to remove small ferromagnetic contaminants from your pipeline bulk streams. Our strongest types can even remove fine weakly magnetic contamination, such as stainless steel 316 wear particles. Magnetic bars are the building blocks of many magnetic filtering systems and come in various magnet qualities, sizes, interface connections, robustness, etc. All types are equipped with a waterproof welded stainless steel 316L housing, and a smoothly polished surface.